Advantages

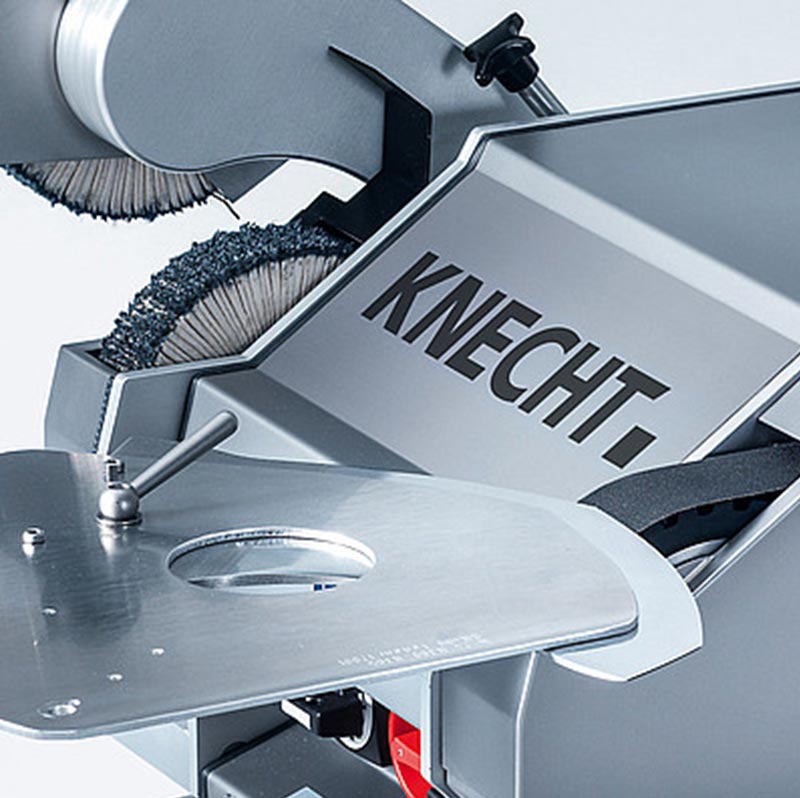

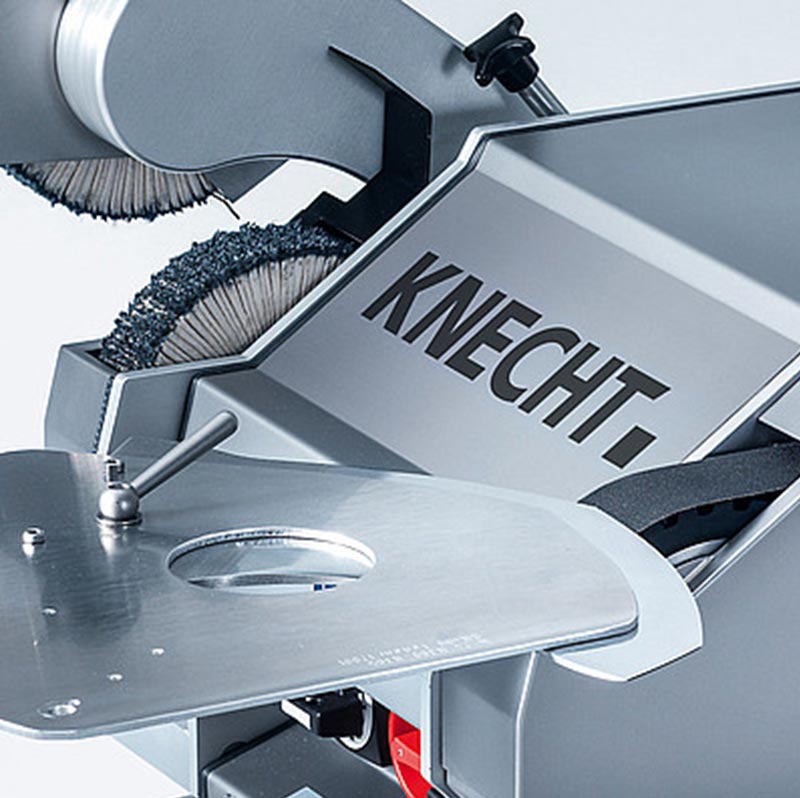

Cup grinding wheel

The cup grinding wheel removes a lot of material very quickly. It is used to easily repair badly damaged cutting tools. Chamfered edges, e.g. on circular knives, are ground on the cup grinding wheel. The required grinding angle is continuously adjustable.

Wet-grinding belt

The wet-grinding belt ensures a very fine cutting tool surface. The profiled rubber contact wheel applies the exact amount of grinding resistance to the knife.

Finned brush

Deburring and polishing of the knives is carried out on the finned brush. The precisely adjusted peripheral speed and the ideally coordinated brush resistance compensate handling errors.

Function disk

Thanks to the patented function disk, the machine is converted in seconds from sharpening sickle shaped cutter knives to linear shaped cutter knives. When changing the knife, a locking mechanism prevents the knife from slewing out unintentionally. It can be changed absolute safe.

Sharpen hand knives

Hand knives are sharpened manually on the wet-grinding belt and deburred and polished on the finned brush.

Grinding circular knives

Circular knives with diameters from 150 – 480 mm are sharpened and deburred on the optionally available circular knife grinding unit.

Grinding belt replacement

When the belt protection cover is opened, the drives are stopped. The tension on the grinding belt is relieved and it can be replaced.

Applications

The Universal Wet-Sharpening Machine S 20 is a universal grinding machine for all conventional cutter knives as well as circular knives, hand knives and other cutting tools. Whether for grinding, polishing or deburring – the cutter knives are clamped in attachments at all times and are therefore guided safely and precisely. The result is a long service life of the cutting edges. For the operators, this means: a high degree of safety with minimum effort. The innovative knife guiding carriage enables sharpening, polishing and deburring of cutter knives in one clamping setup. A coolant pump supplies the individual grinding stations with water. The cutting edges cannot overheat when grinding.