Advantages

Perfect grinding results

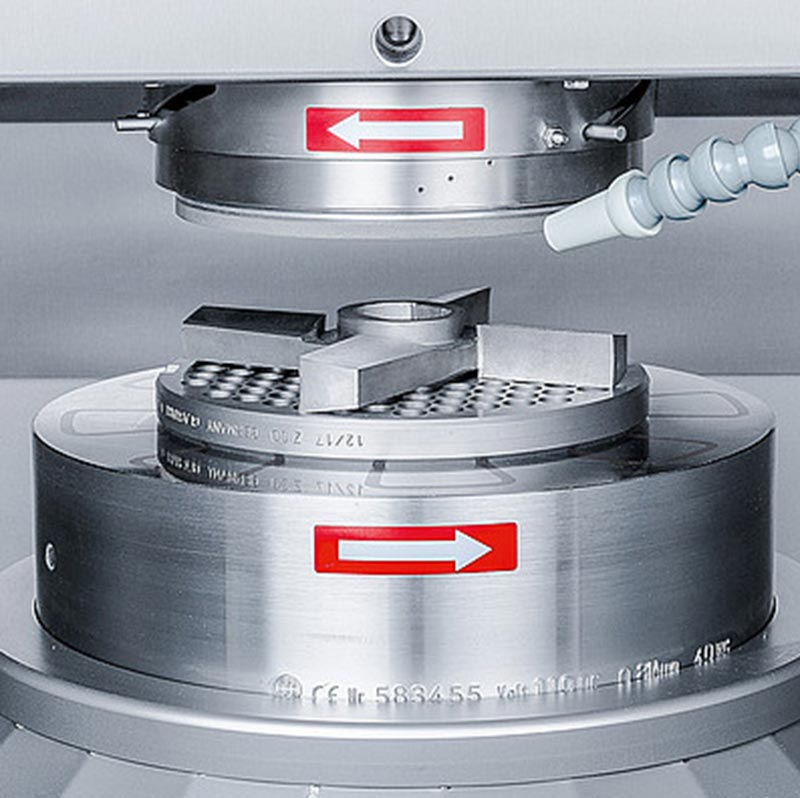

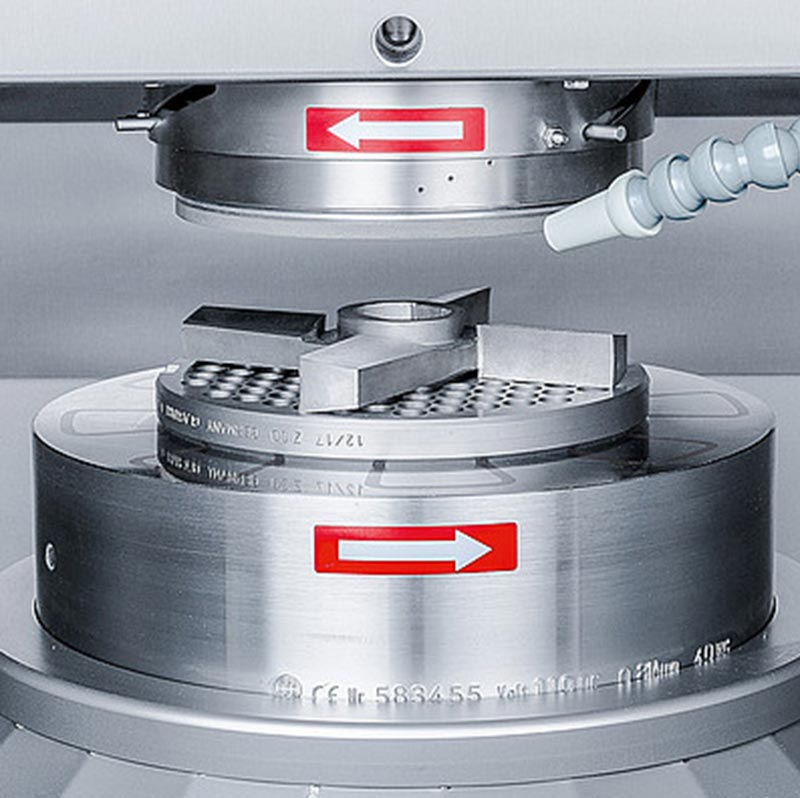

For optimum results with all workpiece diameters, the rotary table has two feed speeds. Moreover, two different clamping options of the cutting tools are available: magnetic or centering pieces. When grinding with magnetic clamping, the heat is ideally dissipated via the rotary table. This ensures optimum cooling at a high material removal rate. The magnetic force can be regulated in six levels. When clamping via centering pieces the clamping magnet is deactivated. This clamping type provides maximum precision for thin and sensitive workpieces.

Precise to the smallest detail

The feed lever for combined operation of rapid feed and fine feed allows the grinding wheel to approach the workpiece very quickly with minimal effort. Nonproductive times are reduced to a minimum by this technology. An electromagnetic brake enables very high feed precision. This ensures that even the smallest quantities of material can be removed.

Suction unit

The suction unit removes floating particles from the encapsulated workroom. This enables visibility during the grinding process. Moreover, it protects the operator‘s respiratory system.

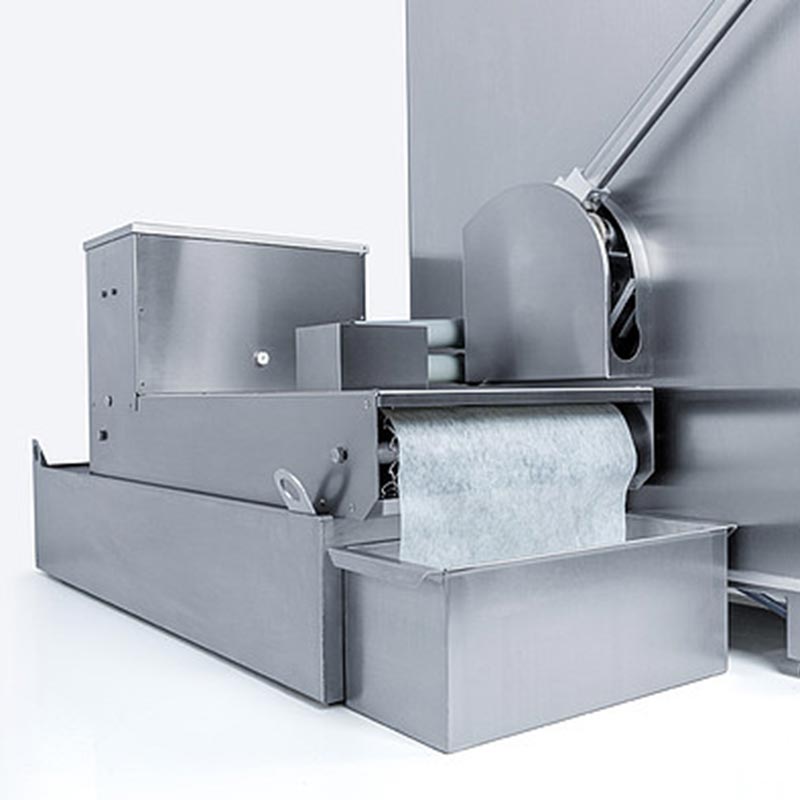

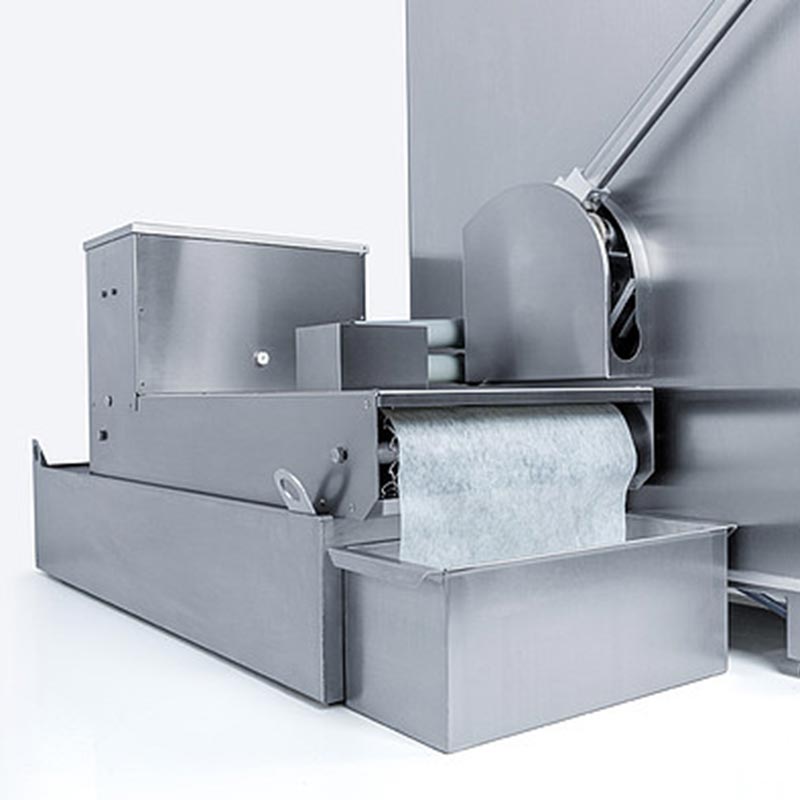

Belt filter coolant unit

The belt filter coolant unit has a volume of 140 l. A filter fleece removes the grinding abrasion completely from the coolant circuit. The removed material is collected on the filter fleece and can be easily disposed of in an environmentally friendly way.

Applications

The machine sharpens mincer plates and knives, cutting sets of inline grinders, as well as cutting sets of emulsifiers with a diameter up to 400 mm (15.7 in). Plane-parallelism is two hundredths of a millimeter.

The strong drive motor and the rotary table are installed in a heavy L-beam construction. This provides a high degree of material removal. Thus, even very worn workpieces can obtain an exact surface again in a short amount of time.

The W 300 coolant circuit ensures continuous cooling of the workpieces. They are reliably prevented from overheating.

If the grinding unit is moved up after the grinding process, all drives, including the coolant supply, stop. The same happens when opening the working room during grinding. To start all drives, it is only necessary to press one button. All systems can be started separately, if required.

The centralized lubricating points make the W 300 particularly maintenance-friendly.