French company SAIREM specializes in the production of batch and tunnel thawing machines using microwaves or radio waves. The product can undergo the thawing process both without packaging and in cardboard or film packaging. Radio waves are mainly used for thawing products in uniform cubes, such as fish. Microwaves, on the other hand, are used for thawing irregularly shaped products, with the thawing process taking 3 to 15 minutes from -20°C to -4°C / -2°C.

SAIREM TMW Microwave Tunnels

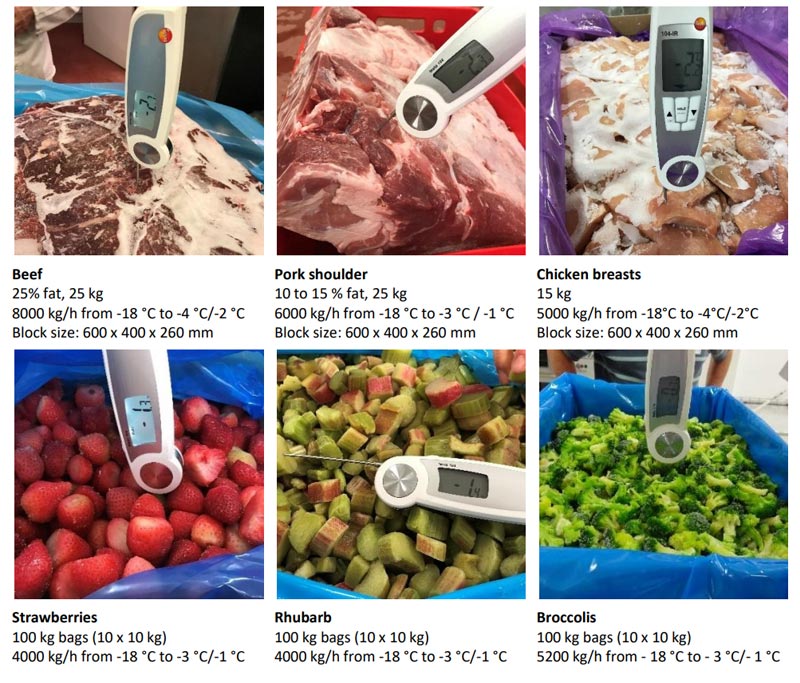

SAIREM TMW microwave tunnel enables rapid tempering or thawing of deeply frozen food. It is suitable for products such as red meat, poultry, fish, fruits, vegetables, cheese, butter, etc. One distinctive feature of TMW is the use of microwave technology to achieve optimal thawing while maintaining quality and uniformity, while ensuring good microwave performance. The large microwave cavity size, microwave length, and cross-coupling of microwaves above and below the blocks are some examples of solutions implemented to achieve the best performance and uniformity.