Advantages

User-friendly control engineering

The W 40 is equipped with a user-friendly touchscreen control system.Three different grinding modes cover all sharpening requirements: Manual grinding, semi-automatic grinding, and fully automatic grinding. Any number of grinding programs can be very easily created by the machine operator. They can be named in plain text and are very easy to recall from the memory.

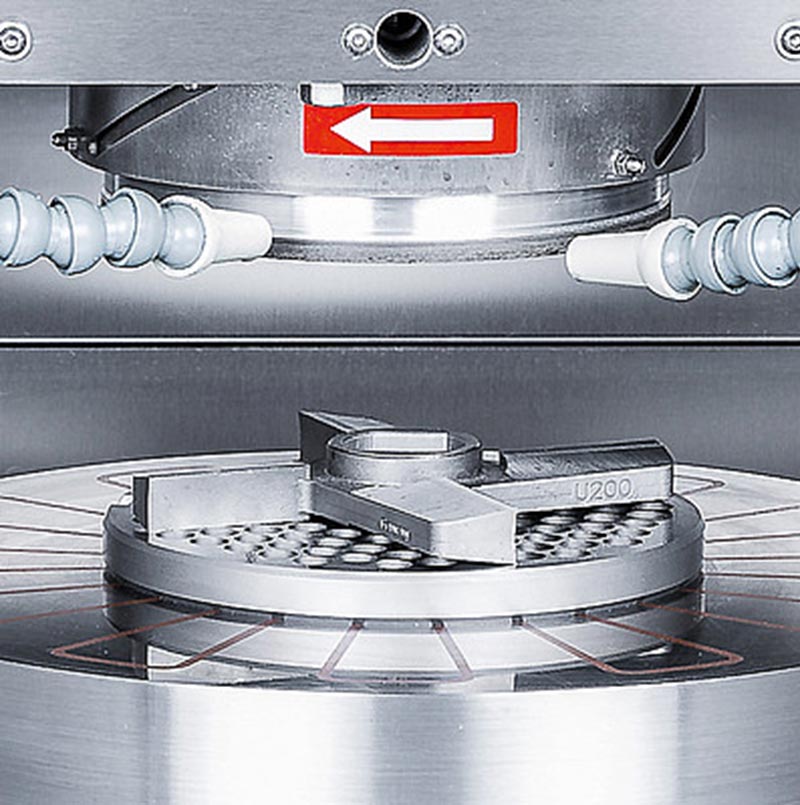

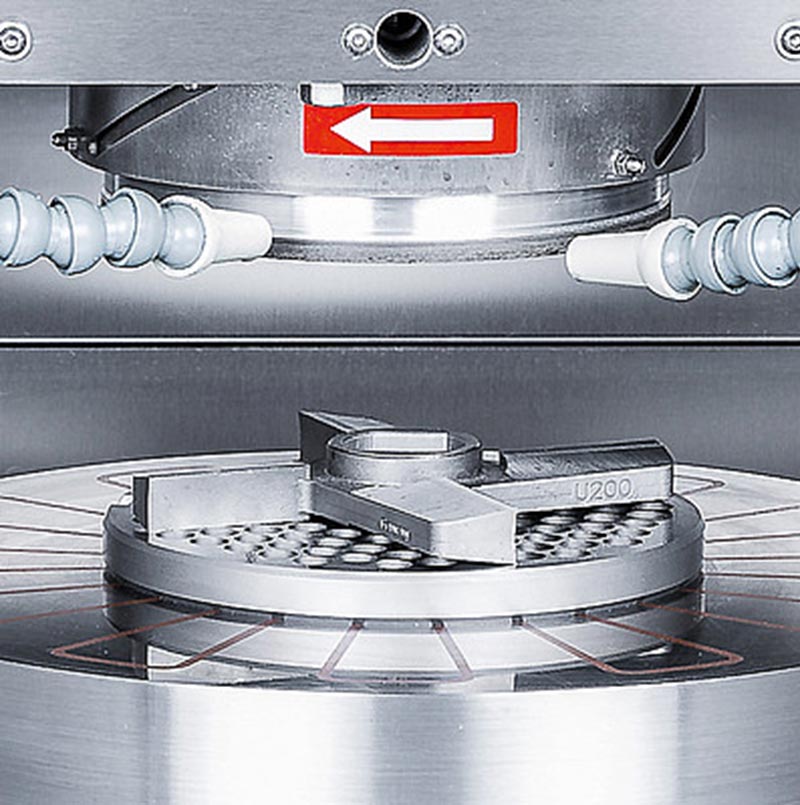

Perfect grinding results

For optimum results with all workpiece diameters, the rotary table has two feed speeds. Moreover, two different clamping options of the cutting tools are available: magnetic or centering pieces. When grinding with magnetic clamping, the heat is optimally dissipated via the rotary table. This ensures optimum cooling at a high material removal rate. The magnetic force can be regulated in six levels. When clamping via centering pieces, the clamping magnet is deactivated. This clamping type provides maximum precision for thin and sensitive workpieces.

Suction unit

The W 40 is completely sealed. The power unit cannot be activated while the door is open. The integrated suction unit removes floating particles from the workroom. This enables visibility during the grinding process. Moreover, it protects the operator‘s respiratory system.

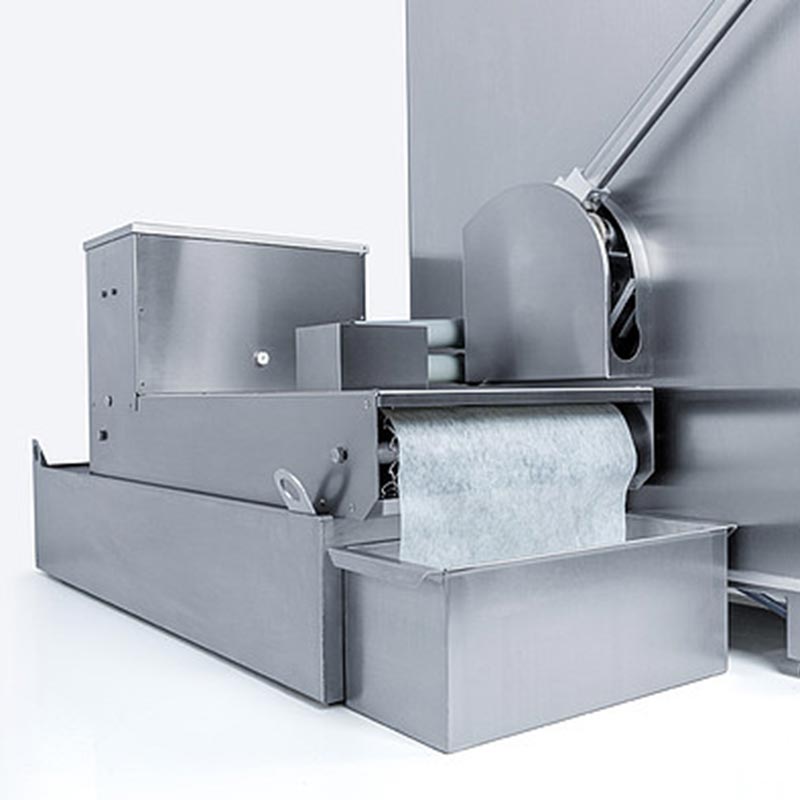

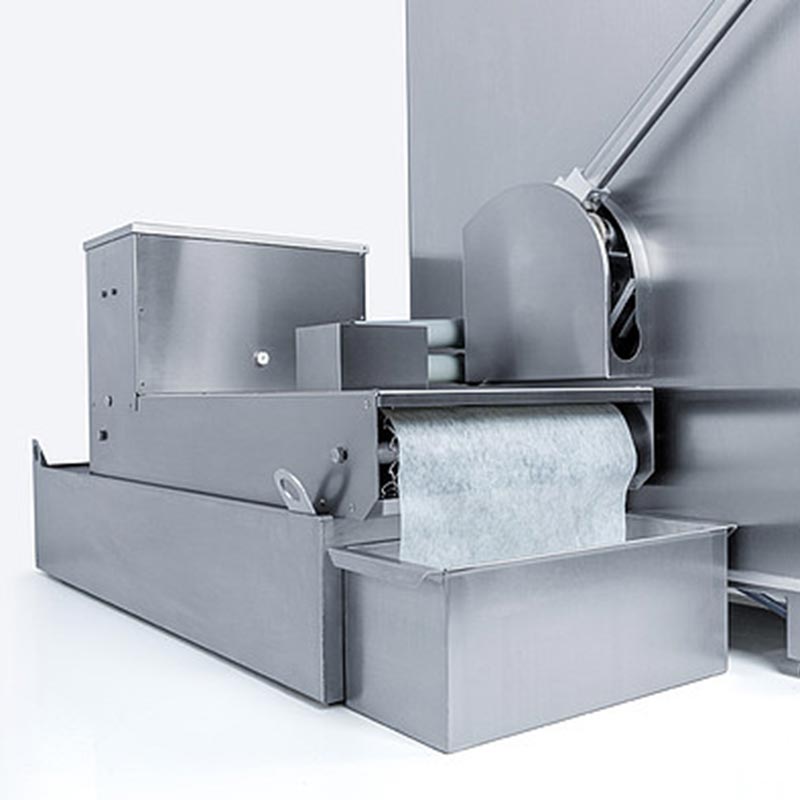

Belt filter coolant unit

The belt filter coolant unit has a volume of 140 l. A filter fleece removes the grinding abrasion completely from the coolant circuit. The removed material is collected on the filter fleece and can be easily disposed of in an environmentally friendly way.

Applications

The W 40 sharpens mincer plates and knives, cutting sets of inline grinders, as well as cutting sets of emulsifiers with a diameter up to 400 mm (15.7 in). Plane-parallelism is two hundredths of a millimeter.

The strong drive motor and the rotary table are installed in a heavy double-T-beam construction. This provides a high degree of material removal. Thus, even very worn workpieces can obtain an exact surface again in a short amount of time.

The coolant circuit of the W 40 ensures constant cooling of the workpieces. Overheating the workpieces is reliably prevented.

The automatic central lubrication system supplies all guide bars and spindles with lubricant. This makes the W 40 very maintenance-friendly.