Advantages

Ergonomic Loading Height:

- Loading height at 1060 mm

- Convenient loading for the operator

Easy Operation:

- Two START – STOP buttons

- Prevents improper operation of the machine

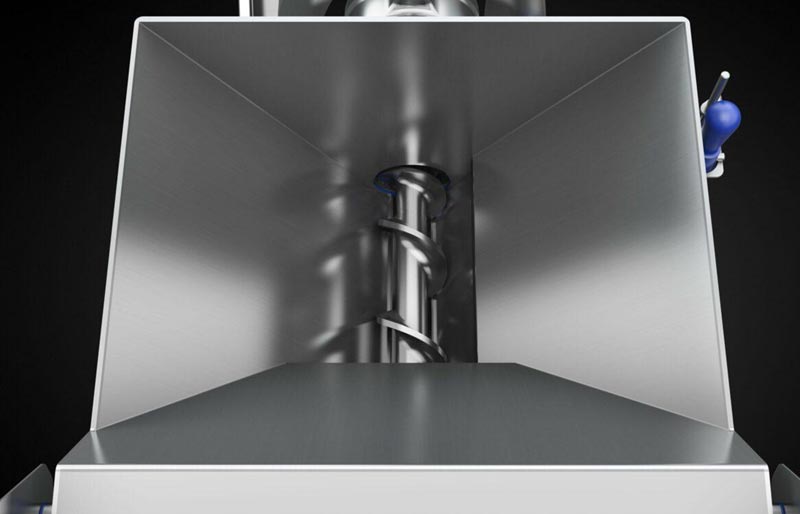

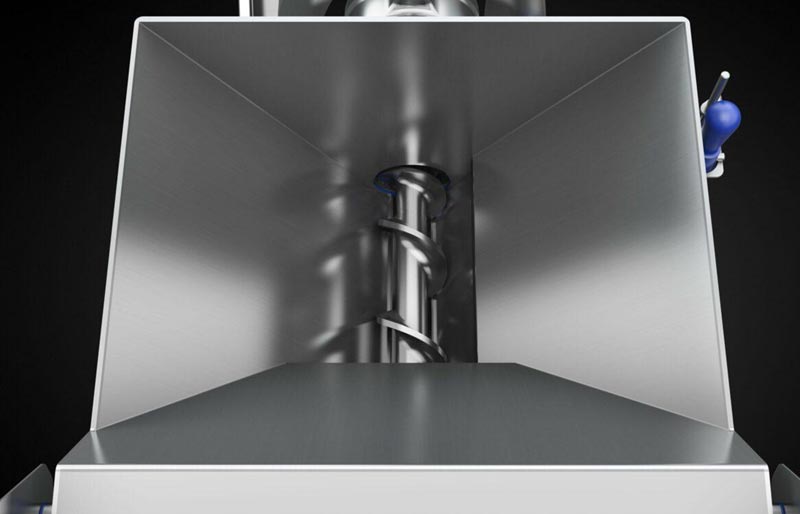

Loading Hopper:

- 10% larger loading hopper compared to the previous version

- Enables better work and higher efficiency

Optimal and Gentle Handling of Material:

- Careful handling of material and complete emptying of the hopper

- Time savings and ensuring efficient meat grinding process

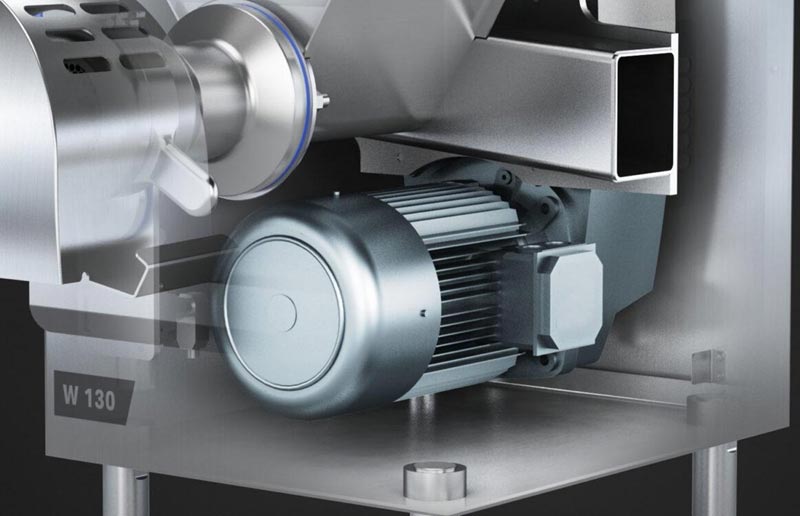

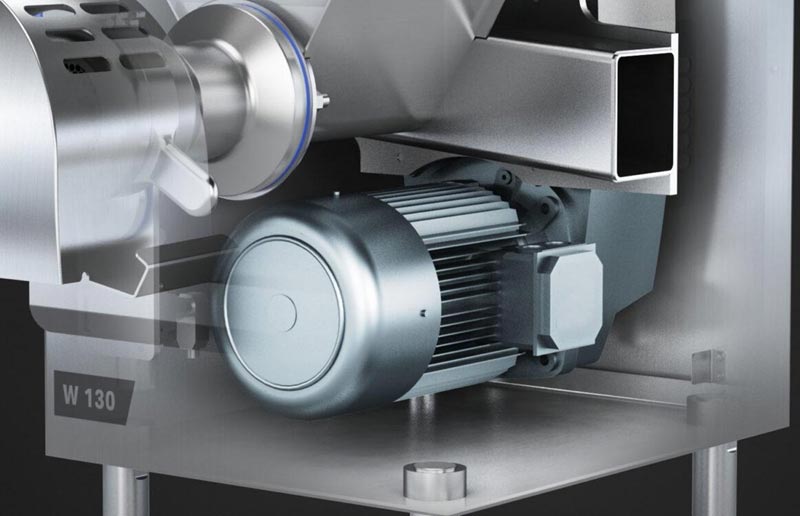

Low Maintenance Costs and Energy-Efficient Drive:

- High efficiency

- Reduced noise level during operation

LASKA Hygienic Design

- Reduces cleaning time and lowers the risk of product contamination

- Documented and proven introduction of LASKA Hygienic Design

Open Channels:

- Possibility to visually check channels and clean the machine without disassembling parts

- Eliminates contamination and reduces the risk of product contamination

Better Bottom Cleaning:

- Better and faster cleaning of the machine bottom thanks to a 300mm gap and adjustable feet

- Reduces cleaning time

Hygiene Certificate issued by the Fraunhofer Institute:

- Hygienic design of components and parts used allows for shorter cleaning time

- Up to 35% time savings on cleaning (compared to the previous version)