Advantages

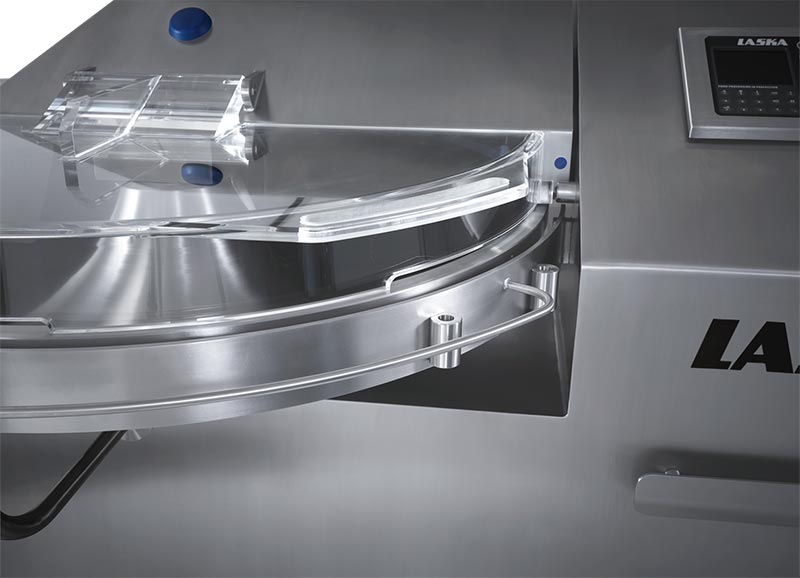

Amazing Cutting Quality

- Small gap between the knife and the cutter bowl measuring 0.8 – 1.3 mm

- Increased quality and homogenization of the product

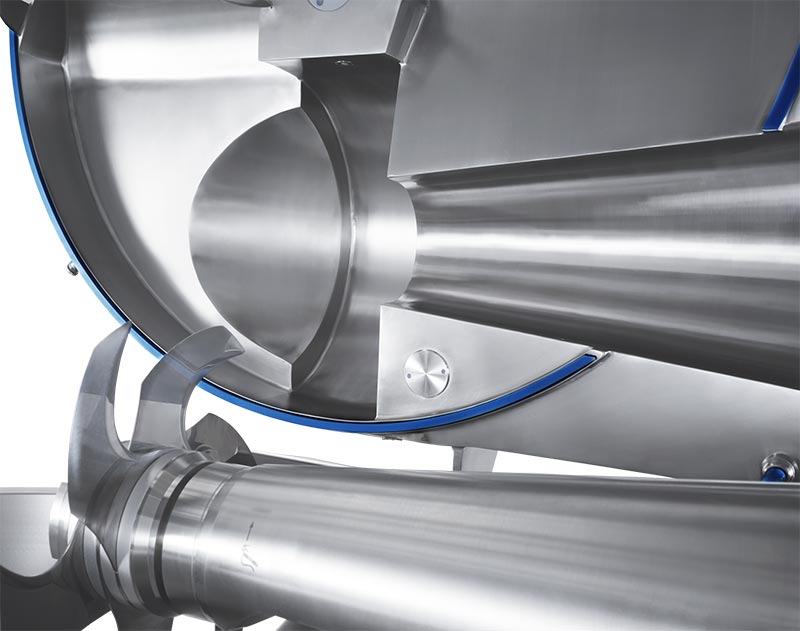

360-Degree Cutting

- Optimized knife guard geometry

- Guaranteed highest product quality in the shortest time

Cutting Speed

- Added ingredients are cut in a precise, gentle, and fast manner, along with the reverse mixing cycle

- Guaranteed highest and consistent product quality

Refined Knife Shaft Bearings

- Bearings developed by Maschinenfabrik Laska tailored for cutting speeds up to 160 m/min

- Increased machine efficiency and longevity

Universal FL-Type Blades

- Easily replaceable blades made of the highest quality steel alloys

- Guaranteed highest quality

Hygienic Sealing of the Knife Chamber

- Special spring-loaded bowl seal prevents product mix leakage

- Minimizes contamination, reduces cleaning time, and minimizes the risk of product contamination