Advantages

Six-axis robot

The central organ of the sharpening machine is the Six-axis robot. It grabs the knife handle, move the knives through the different processing positions and guides them through the sharpening stages, according to its exact shape. The repeat accuracy amounts to 0.03 mm. The robot is completely sealed (IP65) and designed for operating under aggressive work environment conditions.

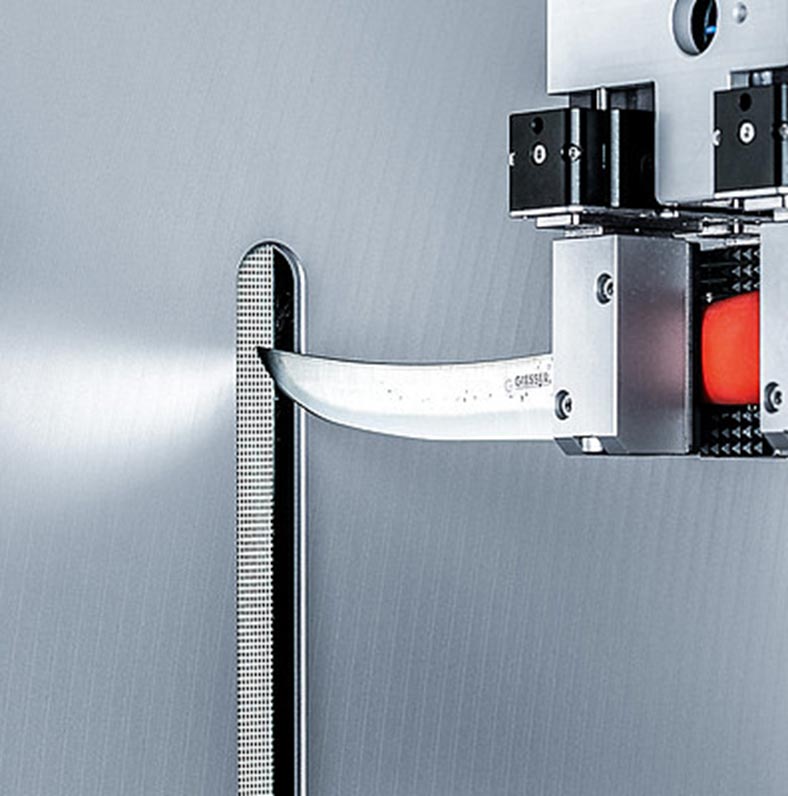

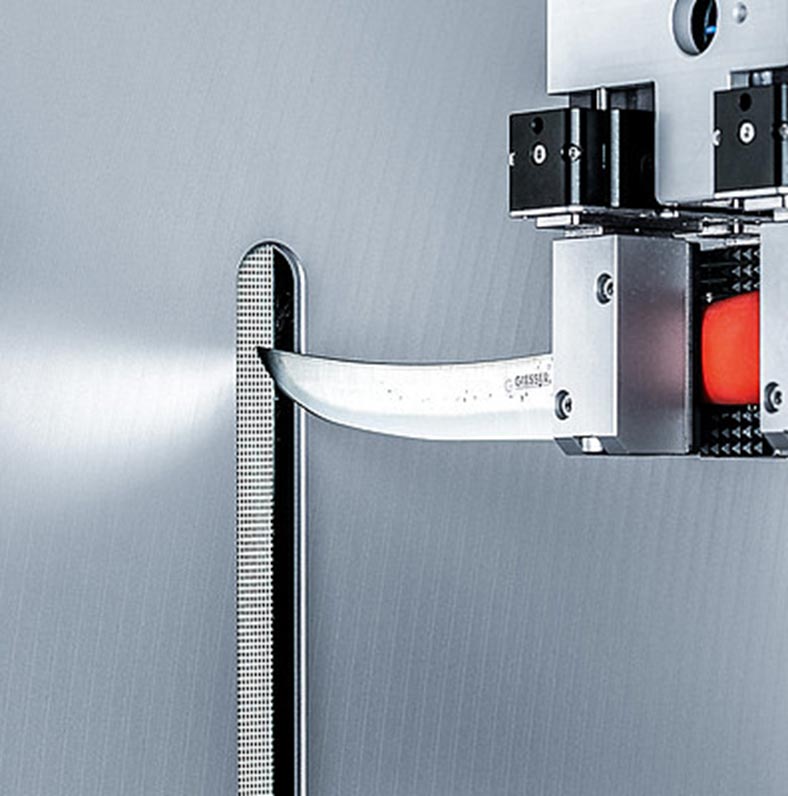

Individual measurement

Before the sharpening program starts, each individual knife is scanned at the measuring station. The detected knife shape is then converted into CNC data. The robot steers the knife, according to this data, through the complete sharpening process. Thus, the original knife shape is retained through every re-sharpening process.

780 hand knives per 8-hour shift,

The E 50 RT has a performance of up to 780 hand knives per 8-hour shift, depending on the shape and size of the knives. The necessary personnel deployment thereby amounts to 1-2 hours.

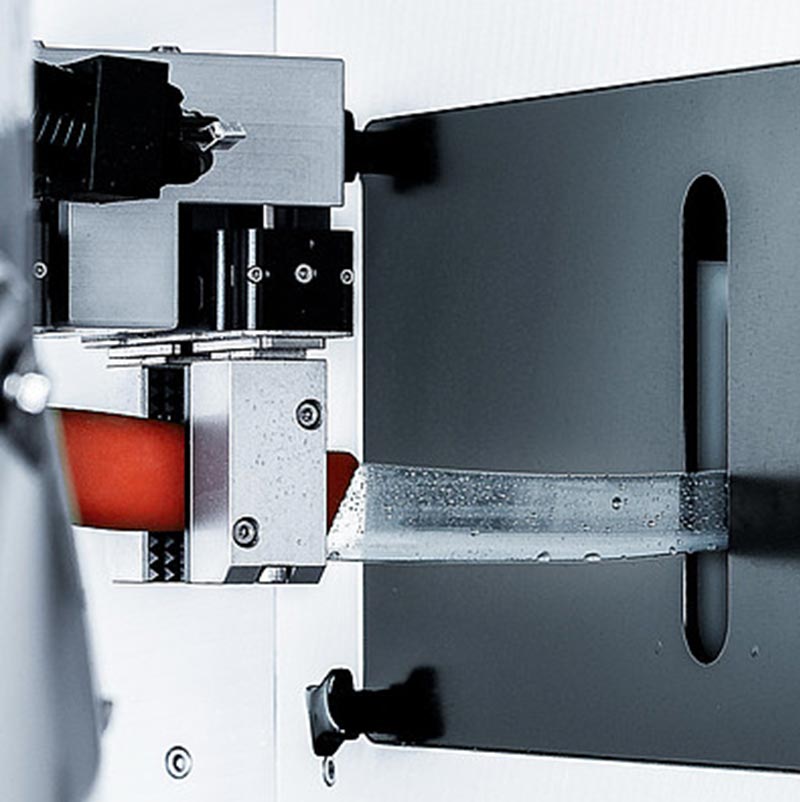

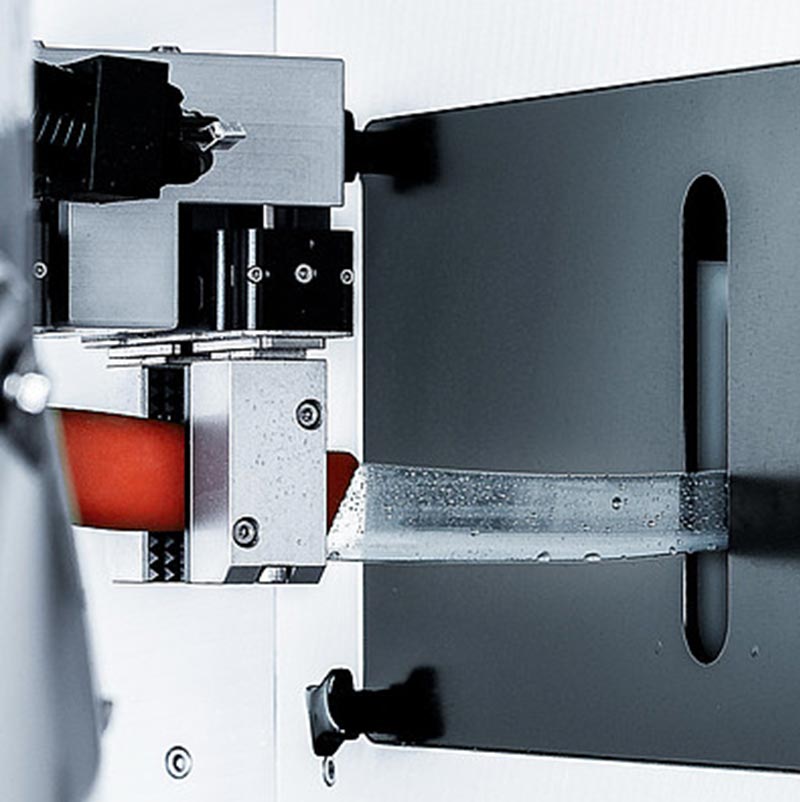

Deburring and polishing

The knife gets its final sharpness when deburring and polishing. This is done quickly and very gently simultaneously from both sides.

Sharpness testing device (optional)

After the knife has been polished, the E 50 RT tests its sharpness fully automatically. The knife penetrates a test medium in the process. The measured sharpness is shown on the display. If the sharpness falls below the minimal value set, the knife is displayed as ‘not sharp’. If the set sharpness is also not achieved with the next knife, the grinding machine shuts down. The reason for the shutdown is displayed.

Health-supporting technology

The serial suction unit and the water cooling considerably reduce all emissions arising from sharpening and polishing. This protects the operator’s respiratory system. The machine room remains nearly clean. This increases the operational safety of the mechanical components. The filtered out grinding and polishing abrasion collects in a tray. There, it can be easily disposed of in an environmentally-friendly way.

Applications

The E 50 R sharpens hand knives of various shapes and sizes fully automatically. The output is up to 780 hand knives per 8 hour shift at 1-2 hours personnel deployment.

The six-axis robot takes the knife out of the magazine – it is optically detected – next, the knife is sharpened, deburred and polished – the robot returns the knife to the magazine.

The magazine consists of two boxes and has space for 60 knives. It can be loaded outside the machine during the operating process.

Since each knife is individually detected before the sharpening process begins, the magazine can be loaded with knives of various shapes and sizes.